Original creator: Light of Devices

In the factory inspection of transformers, many transformer magnetic cores have missing blocks due to the impact of bumps or fixture squeezing. What are the effects of transformer core falling off? This article will discuss the relevant content.

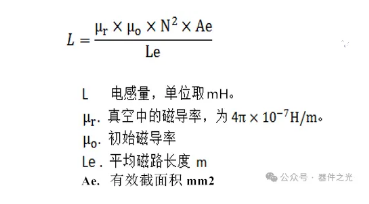

We know that in transformers, the main function of the magnetic core is to provide a magnetic circuit, allowing the transformer to efficiently transfer energy. This can also be well reflected in the calculation formula of inductance:

Generally, we consider the permeability of air as 1, while the permeability of magnetic cores can reach as low as tens, and many can reach thousands or even tens of thousands.

From this perspective, transformers with magnetic cores greatly increase their inductance, and the energy stored and transmitted can also be increased accordingly. The efficiency of their transmission will also be improved to a certain extent.

In addition, the transformer core has a certain structural support effect on the entire transformer product, which helps to maintain the stability of the transformer and reduce noise and vibration.

If there is a missing block in the transformer core, it will affect the normal transmission of the magnetic circuit. After the magnetic core is missing, the original part of the magnetic core becomes air, resulting in an increase in magnetic resistance, a decrease in efficiency, and in severe cases, a decrease in inductance, directly endangering the normal operation of the entire machine.

Some transformers also have missing magnetic cores. During long-term operation of the entire machine, microcracks inside the magnetic core (the part that has not fallen off the block) accelerate and expand, resulting in increased losses and temperature rise of the entire transformer, which in turn leads to the occurrence of machine failure.

From this perspective, the lack of magnetic core blocks in transformers not only affects performance, but also has an impact on the performance and reliability of transformers. At present, the appearance standards for many manufacturers’ magnetic core chipping are: the area of one chipping should not exceed 3% of the entire surface area of the magnetic core, and the area of two or more chipping should not exceed 5%.

Some manufacturers also have some differences, which will not be elaborated here. The essence is the difference in design margins among manufacturers, which leads to different control standards.

Compared to standards, we believe that the reason for transformer core falling off is more important. Especially under the influence of external forces, not only can the surface of the transformer core fall off, but it may also cause cracks inside the transformer core, and the risk cannot be simply evaluated.

In this case, the occurrence of magnetic core breakage in the transformer is even more worthy of our attention and concern.

Post time: Jan-16-2025