Quoted from the Light of Devices

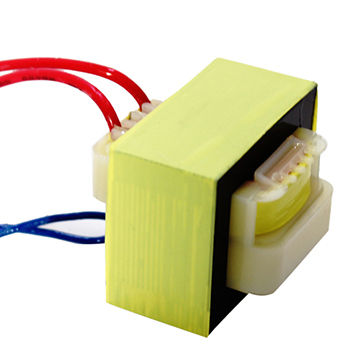

Tape wrapping is a very common process in the production of transformers. So, what are the functions of transformer wrapping tape? This article concludes with a summary.

1. Meet safety regulations. We know that safety regulations are a very important performance in transformers, as they directly affect the safety of end users. Therefore, legitimate products require specialized safety c

According to the requirements, in AC-DC transformers, a minimum distance of 6.4mm must be met between the initial transformers. By wrapping tape between the primary and secondary stages of the transformer for isolation, it can be achieved.

2.Improve electrical performance. Tape can improve the voltage insulation ability between windings and layers of transformers, prevent breakdown during transformer operation, and thus affect the lifespan and stable operation of transformers.

Sometimes, in order to improve the voltage resistance between windings, we also increase the number of layers of tape. Some transformers may use 3 or even 4 layers between the initial windings instead of the traditional 2-layer tape.

3.Prevent corona discharge. Transformers tend to discharge to the outside when operating at high voltage, causing interference to surrounding components. The presence of tape can prevent this tendency, thereby reducing the interference of transformers on the surrounding environment and improving the EMI performance of transformers.

4.Prevent the winding from loosening. During the operation of transformers, the windings are easily loosened by external forces. Using tape can effectively fix the windings, which is beneficial for the stable operation of transformers.

It is worth mentioning that preventing winding looseness is not only during transformer operation. In the manual winding process of transformers, we also need to use tape to fix the winding at the end. Otherwise, if the winding becomes loose when hanging the feet, the wire package will be uneven.

5.Facilitating the winding and wiring of transformers. In the process of transformer winding, it is easy to find that the entire layer is not fully filled. We can solve this problem by adjusting the winding method, such as uniform winding, sparse winding, and centered dense winding.

However, adjusting the winding method can only ensure the flatness of the arrangement of this winding (layer), and cannot guarantee the flatness of the next winding (layer). By wrapping tape, this problem can be avoided to some extent, thereby improving the consistency and efficiency of transformer operations.

6.Protect the internal structure of the transformer. During the production, transportation, and installation of transformers, they may be affected by various external forces. Adhesive tape can provide a certain buffering effect, thereby protecting the interior of the transformer.

7.Fixed. After the assembly of transformer magnetic cores is completed, they are often fixed with tape to prevent significant changes in inductance, which can lead to poor inductance.

By using tape, the magnetic core and wire package can also be perfectly fixed together to form a complete and stable transformer structure, thereby ensuring the reliability and consistency of the transformer.

8.Isolate and insulate from other components. On the periphery of many transformers, tape is often used, even double-layer tape, to completely wrap the entire transformer. In this case, the transformer can be isolated from other components in the entire machine using tape to ensure basic insulation requirements between the components.

Even some power products have height limitations and may wrap the top of the transformer to avoid direct contact between the power supply casing and the transformer, leading to voltage resistance issues.

9.Prevent glue from entering the interior of the transformer. Adhesive entering the interior of the transformer can easily cause thermal expansion and contraction effects, leading to changes in inductance.

In some glued power supply products, in order to prevent glue from entering the interior of the transformer, tape is used to completely wrap the parts of the transformer that are prone to glue to ensure the stability of the inductance.

Post time: Oct-31-2024