Original: Light of Devices

In theoretical calculations, we assume that the AL value for the same magnetic core is fixed and do not consider the influence of other factors on the AL value. However, in practical application, the AL value is influenced by various factors. This article will explain it with examples from group members.

I have a magnetic core with 8Ts coils, and the tested inductance value is around 5.3uH; But when I tested with an 80Ts coil, the inductance value was 610uH. What is the reason for this?

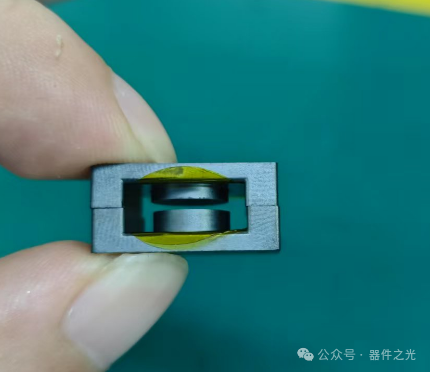

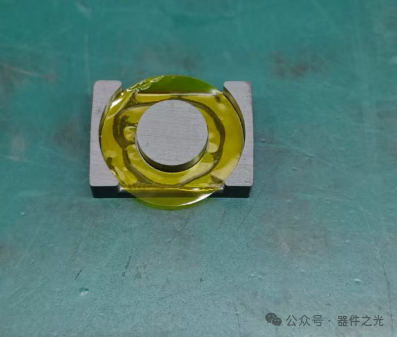

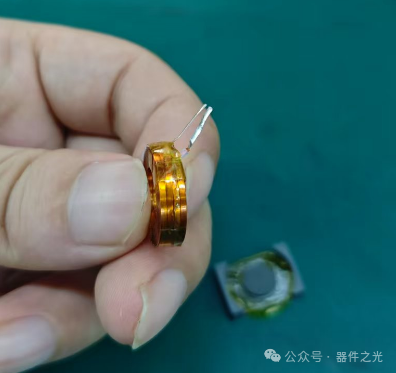

In theory, the 80Ts should be around 530uH. Single coil testing uses the same pair of magnetic cores and this type of flat coil.

Take a picture of the entire product, including the shape of the magnetic core and coil, and whether there is any air gap? The magnetic core factory also defines the AL value as 10 turns, and the normal error is not so large.

When the number of turns is small, the proportion of leakage inductance to inductance will be larger, so the error of inductance will be larger when the number of turns is small; In addition, flat coils will amplify this effect, and if it is a regular coil, the effect may be smaller.

Another issue is testing deviation. When the number of turns is small, the sensitivity is low, and the hysteresis effect has a greater impact on the testing deviation of sensitivity; Of course, there is also a possibility that the magnetic core saturates when the number of turns is small, so the test sensitivity value is not realistic.

There is an air gap, and the product picture is as follows:

The AL values are all test values without an air gap, so it’s normal for you to have an air gap.

We need to consider the influence of air gap here. What type and material of magnetic core? How deep is the air gap?

For this case, I began to consider that it was due to the air gap. Based on the formulas and key points in the article “Calculation and Example Explanation of Air Gap in Transformers”, relevant calculations were carried out.

Comparison reveals that the impact of air gaps is not as significant. (Not repeated here. Interested parties can calculate and compare the difference in sensitivity by combining formulas and basic parameters of magnetic cores.)

Especially for the same magnetic core, the air gap is relatively fixed. 80TS belongs to a situation with a relatively large number of turns. Coupled with the structure, I also thought of the formula L=(0.01 * D * N * N)/(L/D+0.44) for hollow coils. As the number of turns increases, the inductance of each turn increases.

In the case of a large number of circles, this factor will play a dominant role, which makes the explanation reasonable.

There is also data indicating that as the number of turns increases, the inductance coefficient increases because each turn in the coil is equivalent to generating a magnetic flux, which increases with the number of turns.

Based on the case studies, I have verified several more cases, and in this case, the inductance is indeed too large. Unfortunately, there is currently no accurate formula to summarize this phenomenon.

It seems that in mass production, transformers need to use the same coil to grind the air gap, and there are also considerations in this regard.

Post time: Feb-25-2025